FULL SERVICE FOR THE LIFE

OF YOUR OVERHEAD CRANE

Hiring a great overhead crane company is only one piece of your equipment maintenance success. Ace helps you build the processes that ensure you reach your production goals. As a full-service overhead crane manufacturing, distribution and service company our wealth of industry knowledge and decades of experience help us serve the diverse needs of a wide range of customers, comprehensively.

You may take a well running crane for granted but your whole production could be derailed by failing equipment and the expensive headache it brings with it.

By setting up a regular crane inspection and preventative maintenance plan with your Ace representative, you can optimize your asset health and service life through a strategy that tracks and minimizes costs by prioritizing regular inspections for repairs and replacements.

- PLAN A CRANE INSPECTION & PREVENTATIVE

MAINTENANCE PROGRAM WITH YOUR ACE REP - INSPECT EQUIPMENT AS PLANNED

- REVIEW CRANE INSPECTION RESULTS WITH ACE PROFESSIONALS

- CONSULT YOUR ACE REP FOR PRIORITY

CRANE REPAIRS - MAINTAIN A CRANE INSPECTION & PREVENTATIVE MAINTENANCE PROGRAM SCHEDULE

ACE CRANE INSPECTIONS

At Ace, we unite excellent customer service with solid technical knowledge to improve business operations across the nation. We give our best effort to our work and put people first. When an Ace technician inspects your crane, you can expect to hear straight-forward results that include direct, actionable recommendations if needed or the assurance from a skilled professional that your crane is in top shape.

THE CORNERSTONE COMPONENTS OF ACE

INSPECTIONS ARE PREVENTATIVE

MAINTENANCE, SAFETY, INDUSTRY BEST

PRACTICES AND OSHA & ANSI COMPLIANCE

Ace inspections cover up to 250 points on your crane, all the potential problem areas we’ve seen in decades of experience servicing material handling equipment. We inspect the most critical components and their supporting elements, and where practical, we’ll take a hands-on approach and open covers when a simple visual scan is not possible. Your easy-to-read Inspection Report will document any problem areas and needed repairs. The photos generated will help you get a visual sign-off for any issues or deficiencies involved.

CRANE AND HOIST INSPECTION PRICING

| ELECTRIC CHAIN HOIST INSPECTION | $125 | 51 Standard Points Inspected | *All prices listed do not include runways and travel time. |

| JIB, MONORAIL OR SMALLER CRANE INSPECTION | $125 - $175 | 44 Standard Points Inspected | |

| SINGLE GIRDER CRANE INSPECTION | $150 - $225 | 48 Standard Points Inspected | |

| DOUBLE GIRDER CRANE INSPECTION | $250 - $300 | 48 Standard Points Inspected |

HOW OFTEN SHOULD YOU INSPECT YOUR CRANE?

| TYPE OF CRANE INSPECTION | INSPECTION FREQUENCY |

|---|---|

| Initial Inspection | Prior To Use of New or Altered Cranes |

| Pre-Shift Functional Test | Beginning of Each Shift |

| Frequent Inspection | Required Monthly or at Defined Intervals |

| Periodic Inspection | Annually to Quarterly (Based on Duty Cycle) |

| Not In Regular Use | Idle for 1 month+ but < 6 Months |

| Preventative Maintenance | Based on OEM Recommendations |

| Repairs and Adjustments | Existence of Unsafe Conditions |

THE TOP 5 MOST COMMON ISSUES FOUND DURING

CRANE INSPECTIONS

HOIST WIRE ROPE WORN OR DAMAGED

Wire rope hoists are the true workhorse components of heavy duty industrial overhead cranes. With proper care and maintenance, your strong and reliable wire rope hoist will last you through decades of service. Because of their frequent use and handling, over time, the wire rope may need replacement. The rope itself, made up of multiple individual woven strands of wire, may become kinked, crushed, rusted or deformed from use. Consistent side pulling, an improper use of a hoist, may create case creasing and cause the rope to skip over grooves. Overuse and fatigue bends or breaks the strands, exposing the inner core and making it vulnerable to breakage.

Failure to replace or properly lubricate a damaged wire rope on your hoist could lead to equipment failure. Make sure your wire rope hoist is fit to operate smoothly with regular inspections.

HOIST CHAIN WORN OR DAMAGED

Similarly to wire rope, load chain on a hoist can become worn or damaged and might need replacement over time. Any dust, corrosion, grime and grease build up can affect hoist performance and needs to be cleaned.

Excessive wear due to heavy usage is the most common issue reported in load chain inspections. A worn chain may not allow for proper guiding or catch in the hoist lifting sprockets, affecting hoist performance. Chains can also become twisted and need re-reeving or replacement. If a hoist is working in overheated conditions such as in a chemical plant or placed near a furnace, this may cause heat or rust damage, corrosion or dry out the chains.

If load chain has been repaired with welding it will need to be replaced. Welded chain is not reliable and leaves the chain more vulnerable to future breakage. Regular inspection of load chain can prevent these kinds of issues.

For more information, see Ace’s video on How to Inspect Load Chains.

TROLLEY BUMPERS DAMAGED OR MISSING

A rubber or polyurethane bumper is used for reducing horizontal impact when a moving crane or trolley reaches the end of its permitted travel, or when two moving cranes or trolleys come into contact or can serves as an emergency backup to safety limits. This device may be attached to the bridge, trolley, or runway stop. ASME regulations require the use of shock absorbing bumpers on motorized trolleys on overhead cranes. ASME B30.2-1.8.2 and B30.17-1.9.3: Bridge Bumpers (a) “A power-operated bridge shall be provided with bumpers or other automatic means providing equivalent effect.” ASME B30.2-1.8.3 and ASME B30.17-1.9.4 Trolley Bumpers (a) Power-operated trolley shall be provided with bumpers or other automatic means providing equivalent effect.

If a bumper becomes damaged during normal operations in a way it is no longer useful, it will need to be replaced.

The most common issue found in inspections regarding bumpers is lack of a bumper on overhead crane equipment. When a bumper is missing, there is nothing to absorb the impact in case of a collision which could cause tremendous damage to the crane.

An inspection will flag any missing regulation safety equipment on your overhead crane.

GEAR CASE LEAKS

Gear cases on overhead cranes need to be inspected periodically for cracks and oil leaks. Leaks are a common find during gear case inspections and can indicate anything from a faulty seal to a loose mounting plate. It’s important to repair the leak issue so that fluid does not fall onto and coat other crane components such as a catwalk, making it slippery and dangerous for employees to walk on or fall into the motor or brake, which could disable your crane.

Preventative maintenance on crane gearboxes should include removing dirt and grime and replacing gaskets, seals and sealants.

FESTOON WIRING DAMAGE

The festoon is an insulated set of wiring that drapes like a ribbon along the side of a crane, providing power to a runway, power and control to a bridge crane, or lower voltage control to a separate pendant station circuit. Cable festoons support flat or round cables in a series of cable carriers that move freely along an I-beam track. There are many ways festoon insulation or wiring can get damaged, affecting flow of power to the unit. If the festoon drapes too low it can hit other components, like the collector hangers.

In an inspection of the festoon, the technician looks for this type of damage as well as if the customer has spliced the wiring or tried to bandage damaged wiring themselves. In any of these cases, it is best to replace the festoon.

“THE CREW AT ACE COME READY TO WORK AND THEY REALLY KNOW WHAT THEY’RE DOING!

ACE IS A HUGE ASSET TO US.”

—R.E., MANAGER, METALS INDUSTRY

TRACKING YOUR CRANE INSPECTIONS,

REPAIRS AND EXPENSES IS EASY!

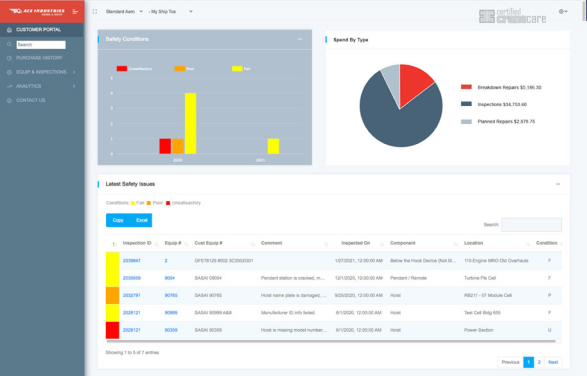

As an Ace Inspection customer, you’ll have access to your records and job data online anytime you need it! Just login to your customer portal to view:

Your Customer Dashboard for your latest safety issues, trending safety conditions and a log of all your open jobs.

Your Purchase History for a chart of your spending to date, a view of 12 month purchasing trends and detailed invoices.

Your Equipment and Inspection Logs by location. Keep track of all inspection and repairs activity on your equipment in sorted categories, such as by location.

And Helpful Analytical Data such as your equipment spend by category, breakdown and repair hours, expense trends by year, your spend in materials vs labor, your repair hours and safety observations.

All you need to know about your equipment is at your fingertips, 24/7!

Disclaimer—Ace Industries protects the rights of our customers and honors their non-disclosure requests to withhold name of company and employee for case studies, direct quotes and testimonials on aceindustries.com. Initials and job titles used for identification reference only.